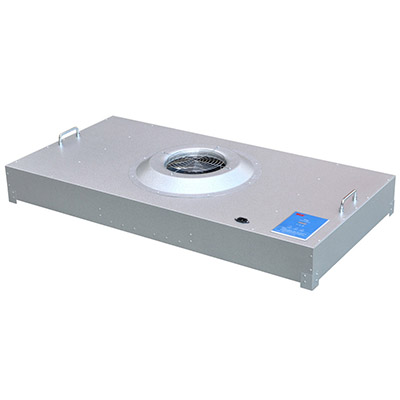

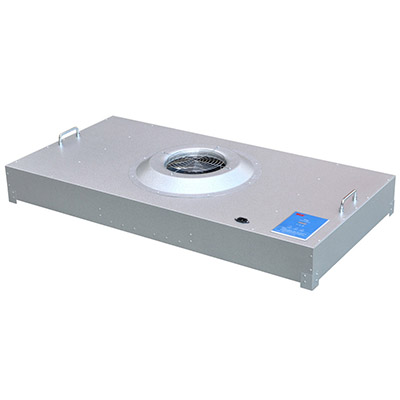

Made with HEPA-filter, fan and control system, our fan filter units (FFUs) provide a clean air flow to counter health hazards workers face in occupational dusty environments. As such, our FFUs ensure the air quality of cleanrooms, laboratories, medical facilities or microenvironments by extracting the contaminants from the working area.

Compo offers FFUs in various specifications, flow rate, and filtration options to cover any budget and project requirements, making our units precisely suited for any application. Call us today for timely technical support.

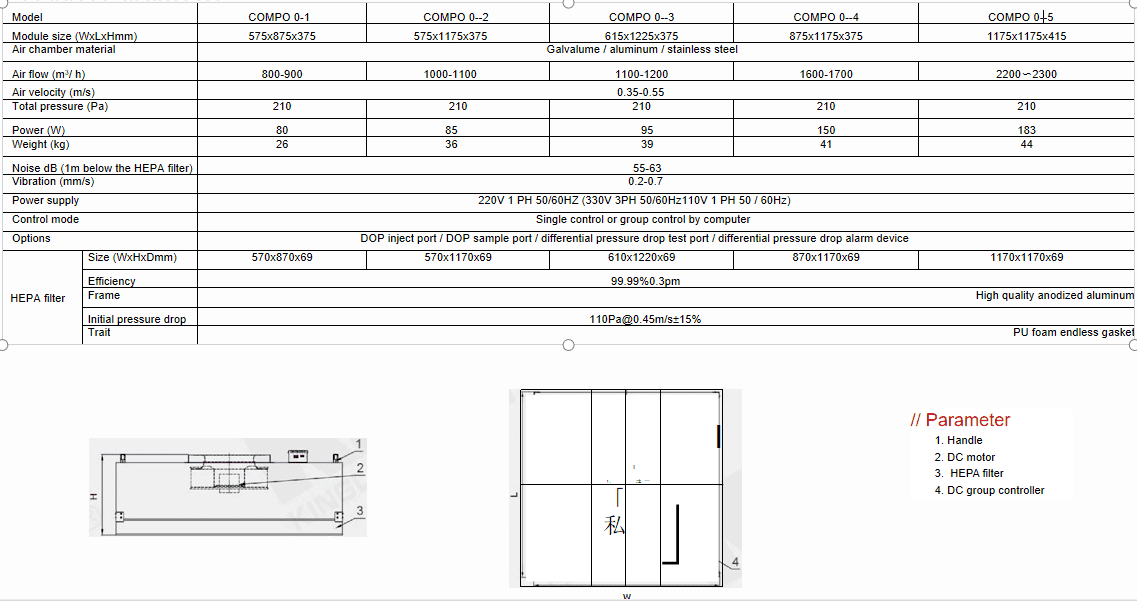

Alternating current motor for making Fan Filter Unit.

AC system is generally in 100-300W

Direct current motor for making Fan Filter Unit.

DC system is generally in 50-220W

Customized FFUs deliver expected results while being made more affordable and available for your market.

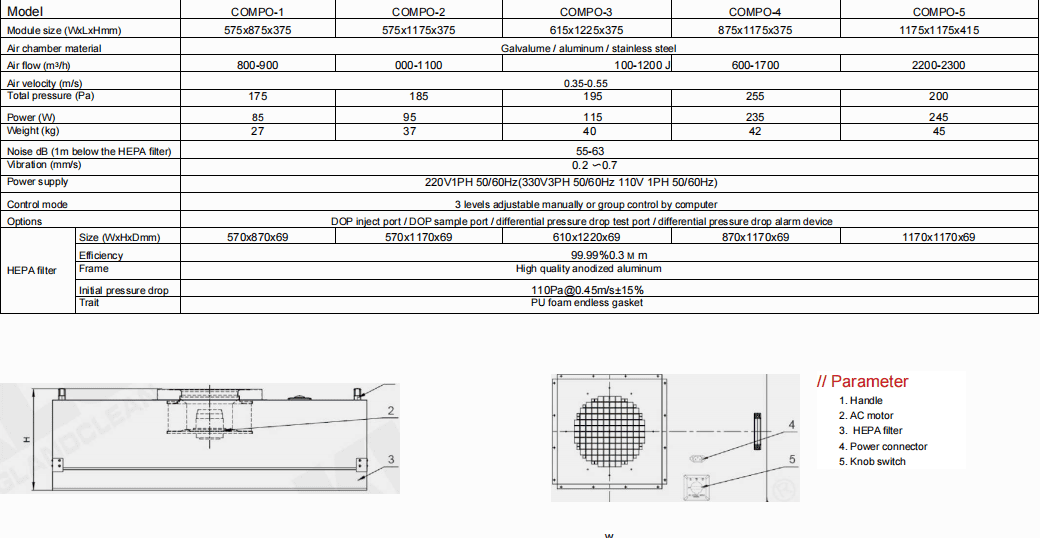

Due to their energy-saving capabilities, our FFUs can work for long periods and make low noise, offering much convenience.

Every FFU model comes with uniform wind speeds and lower vibrations thanks to its advanced stepless speed regulation capabilities.

While the system is in operation, our FFUs are faster to install and can be easily accessed for repair or replacement when needed.

FFU is widely used in cleanrooms, hospital operating rooms, laboratories, the bio-pharmaceutical industry, microelectronics, semiconductors, liquid crystal manufacturing, precision machinery, optical, film and fiber optic equipment and food price and other clean air demanding working environments.

Crucial for maintaining cleanroom environments, our fan filter units are in high demand and made in different designs to suit varied requirements. Flexible and easy to install, our filters can either be suspended or hung from any cleanroom ceilings. Our FFUs use a HEPA filter to generate a clean flow of indoor air through two filtration stages and free the area of particles and contaminants.

We will pack the Fan Filter Units in three-layer corrugated cartons. Then the shipping cartons put on pallets. We will ensure that the FFU will be in safe condition during long-distance transport.

If there is any damage after customers receive the shipment, we shall be responsible for it.

Fast services, reliable factory production and consistent testing provide you with premium quality fan filter units.

Compo’s services are supporting all steps of the production workflow beyond manufacturing, from consultation to finished product. Through careful research and professional consultation sessions, we look into your situation in detail and thereby give a reasonable solution of air cleaning. By keeping you informed at every stage, we ensure peace of mind. We respond promptly within 12 hours to tackle your needs.

Compo is committed to providing customers with high-quality FFU Fan filter unit, thus gaining a good reputation in the market. See what our clients have said to us.

FFU , called Fan Filter Unit ,also known as “air cleaner”, air freshener, or purifier, refers to an air purification machine that is able to adsorb, decompose or transform a variety of air pollutants (generally including PM2.5, dust, pollen, odor, formaldehyde, and other renovation pollution, allergens, etc.), effectively improve the cleanliness of the air products. It can be used for household, commercial industrial, and building.

FFU purifier has a variety of different technologies and media that enable it to provide clean and fresh air to users. Commonly used air purification technologies are: adsorption technology, negative (positive) ion technology, catalytic technology, photocatalyst technology, super structured light mineralization technology, HEPA high efficiency filtration technology, electrostatic dust collection technology, etc.; material technology mainly includes: photocatalyst, activated carbon, synthetic fiber, HEPA high efficiency materials, negative ion generator, etc. The existing air purifier is mostly adopted as compound type, that is, a variety of purification technology and material media are used at the same time.

Electrostatic dust removal.It can filter dust, smoke and even smaller than cells to prevent lung disease, lung cancer, liver cancer, etc.. Dust smaller than 2.5 microns is harmful to the human body because it can penetrate cells and enter the bloodstream. Ordinary purification machines use filter paper to filter the dust in the air, it is very easy to block the filter pores, dust not only no effect, but also easy to cause secondary pollution.

2. Strongly kill airborne germs, neutralize volatile organic compounds, formaldehyde, benzene, pesticides, foggy hydrocarbons, and harmful gases emitted from paints, and prevent physical discomfort caused by inhalation of harmful gases. The electronic dust collector device releases the right amount of ozone (O3), which can kill the virus in the air. The killing mechanism is to destroy the four polypeptide chains of the virus capsid protein and damage the RNA. Therefore, ozone is widely used in tap water, swimming pools, tableware, and food without the slightest contamination.

3. High-efficiency dust collection and bacteria collection, to prevent airborne microparticles, dead skin flakes, dust, pollen, and other conditions that cause dry skin, allergies, etc. The use of current type PWM high-frequency conversion technology can make the dust collector in the case of load dust, but still can be better dust collection and bacteria collection. The electronic dust collector can adsorb dust and germs smaller than 0.3-0.5 microns. The dust in the air that is harmful to people* is dust smaller than 10 microns, which can enter human cells and cause various diseases, especially heavy metals such as lead and cadmium in the air, which can easily cause cancer.

4. Primary, medium, and high-efficiency three-layer purification, biological pollutants in the air, effective prevention and control of virus infection. Kill and destroy bacteria, viruses, and molds in the air and on the surface of objects, to prevent diseases caused by airborne contaminants, epidemic viruses, etc., to reduce the spread of germs in the air. Eliminate the “flu phenomenon” that one person has a cold and the whole unit has a cold.

FFU is mainly composed of a motor, fan, air filter, and intelligent monitoring system, some models of the machine are equipped with humidification functions of the water tank, or auxiliary purification devices, such as a negative ion generator, high voltage circuit, etc.. The air filter is the core component. Other purification devices actually play only auxiliary functions, so the air filter is a key factor that directly affects the effect of the air purifier.

Motor and fan: motor fan as the core of the air purifier is also an essential accessory, its main role is to control the air to circulate the flow. The air with pollutants will be sucked in and then filtered before blowing out the clean air.

ir filter (filter): most FFU on the market mainly filter to achieve the purpose of air purification, and the filter is mainly divided into particulate filters and organic filters. Particulate filters are divided into coarse filters, and fine particulate filters; organic filters are divided into formaldehyde filters, deodorization filters, activated carbon filters, etc.. Each filter is mainly for different sources of pollution, and the principle of filtration is also different.

Water tank: As air purifier is getting more and more attention from consumers, the function of air purifier is not only limited to air purification only, by adding a water tank structure design, an air purifier can also play the role of humidification of air while completing the basic mission.

Intelligent monitoring system: Intelligent monitoring system is simply understood as the supervisor of air quality, through the built-in monitoring equipment can make a real-time judgment of the quality of the air in good to poor, consumers can choose to use the air purifier according to the air quality situation. In addition, the intelligent monitoring system can also monitor the life of the filter to the water level of the water tank, etc., so that users can easily understand the working status of the air purifier.

Negative ion generator with high voltage circuit: Generally used as an auxiliary purification function, mainly to send negative ions along with clean air. Negative ions have functions such as hypnotic, analgesic, and appetite increasing. After a thunderstorm, people feel relaxed, which is the reason for the increase in negative ions in the air. Air-negative ions can restore pollutants from the atmosphere, nitrogen oxides, cigarettes, and other reactive oxygen species (oxygen radicals), reducing the harm of excessive reactive oxygen species on the human body.

Purification device: electrostatic air purification device in terms of its structure, there are three products on the market: flat structure air purification device, honeycomb hexagonal channel air purification device, and round hole channel air purification device.

Unique low vibration and low noise; excellent air uniform distribution performance; automatic constant or graded air speed adjustment; advanced mechanical performance and reliability; advanced mechanical performance and reliability.

High-efficiency particulate air filter (FFU purifier) is one of the popular technologies used in air purification. The standard HEPA filter can absorb 99.7% of suspended particles of size 0.3 microns (0.3 microns is * difficult to filter size), but its wind resistance is also relatively large, generally rarely used in air purifiers, the actual air purifier manufacturers claim that HEPA is actually not the real HEPA its filtration efficiency is slightly lower than HEPA, wind resistance is also relatively low. Whether it is a real HEPA or a promotional HEPA is to make the inhaled air fresher and cleaner. The filter absorbs chemical fumes, dust particles, and pollen, and after being filtered by the air purifier, the air is free of these pollutants.

The advantage of HEPA filters (FFU purifiers) is that they are effective** and are the main technology for removing particulate pollutants from the air, but the disadvantage is that they can only filter out suspended particles and cannot filter out harmful gases. Air cleaners using HEPA should have a good airtight design, otherwise, the air will bypass the filter and lose its filtering effect.

The working principle of FFU purifiers is mainly divided into three types: passive, active, and mixed active-passive.

According to the FFU purifier for airborne particulate removal technology, there are mainly mechanical filter types, electrostatic electret filter types, high-pressure electrostatic dust collection, negative ion and plasma methods, etc.

Mechanical filtration

Generally, the particles are mainly captured in the following four ways: direct interception, inertial collision, Brownian diffusion mechanism, and screening effect, which is good for the collection of fine particles but large wind resistance, in order to obtain high purification efficiency, the resistance of the filter is large, and the filter needs to be dense leading to a reduced life expectancy and needs to be replaced regularly.

High-pressure electrostatic dust collection

The use of a high-voltage electrostatic field to ionize the gas so that the dust particles charged adsorption to the electrode dust collection method, although its wind resistance is small, the larger particles and fibers trapping effect is poor, will cause discharge, and cleaning trouble and time-consuming, easy to produce ozone, the formation of secondary pollution.

FFU laminar flow unit module can be connected, which makes FFU widely used in clean rooms, clean benches, clean production lines, assembled clean rooms and laminar flow hood, etc. FFU is equipped with primary and high-efficiency filters. The air is drawn in from the top of the FFU by the primary and high-efficiency filters, and the filtered clean air is sent out at a uniform speed of 0.45m/s±20 on the whole air outlet surface. It adopts new American technology and is suitable for clean environments obtained in various environments. It provides high-quality clean air for clean rooms and micro-environments of different sizes and sizes and cleanliness levels. In the new clean room and clean plant renovation, it can improve the cleanliness level, reduce noise and vibration, and also greatly reduce the cost, easy to install and maintain, so it is an ideal part of clean environment.

Mechanical filtration

Generally, the particles are mainly captured in the following four ways: direct interception, inertial collision, Brownian diffusion mechanism, and screening effect, which is good for the collection of fine particles but large wind resistance, in order to obtain high purification efficiency, the resistance of the filter is large, and the filter needs to be dense leading to a reduced life expectancy and needs to be replaced regularly.

High-pressure electrostatic dust collection

The use of a high-voltage electrostatic field to ionize the gas so that the dust particles charged adsorption to the electrode dust collection method, although its wind resistance is small, the larger particles and fibers trapping effect is poor, will cause discharge, and cleaning trouble and time-consuming, easy to produce ozone, the formation of secondary pollution.

First, the filter material. Good filtration materials (such as HEPA high-density filter media) adsorption capacity of more than 0.3 microns of pollutants up to 99.9% or more.

Second, purification efficiency. If the room is larger, you should choose the air purifier with a large purification air volume, for example, a room of 15 square meters should choose the air purifier with a unit purification air volume of 120 cubic meters per hour.

Third, service life. As the purification filter bile tends to saturate, the adsorption capacity of the purifier will decrease, so consumers should choose the purification filter bile with a regeneration function to extend its life.

Fourth, the room layout. Air purifier air inlet and outlet have a 360-degree ring design, there is also a one-way in and out of the air, if you want the product in the placement of the room layout is not limited, you can choose the ring in and out of the air design products.

Sixth, after-sales service. The purification filter gall needs to be replaced by the manufacturer after the failure, so you should choose the products of the company with perfect after-sales service.

1.We suggest that if the larger clean room has a higher clean level of requirements, then we centralized the air conditioning unit air volume, and fan pressure head higher to overcome the resistance of the ducts, as well as the resistance of the primary filter, ineffective ground filter, high-efficiency filter to meet the needs of these rooms cleanliness, which will lead to higher overall operating costs of air conditioning, while those higher clean level of The cleanliness effect of the room may not meet the demand. And centralized air supply system as long as the air conditioner fails, it will cause the air conditioner involved in all the clean rooms to stop running.

2. The problem of small space in the ceiling of the FFU net room.

The individual clean room needs a hundred or ten laminar flow hoods for process demand, then the clean room ceiling will set up a huge air supply static pressure box, static pressure box set up ventilation fan, these static pressure boxes together with the air supply pipe, return air pipe occupies a lot of space, making the maintenance space becomes small, and sometimes even affect the use of fire escape.

If we use FFU, it is different, the ceiling of a clean room is divided into several modules, and each module is an FFU, so we can adjust each module (i.e. FFU) to meet the requirements of the pressure balance of the upper ceiling air supply static pressure box, thus greatly reducing the requirements for the height of the static pressure box. At the same time, the huge air supply and return ducts can be saved, so the installation space can be saved. Especially when the renovation project is limited by the height of the floor, FFU effectively solves this problem.

3.FFU air supply system uses a static pressure box for negative pressure, so even if there is a leak in the air outlet installation, it will leak from the clean room to the static pressure box, which will not form pollution of the clean room, which is also a good advantage.

We satisfy all your air filtration requirements and would love to be your partner.

Be the first to know about regular product updates and promotion offers.

Copyright © 2022, Compo. All rights reserved. Powered by Compo

WhatsApp us