Compo is a global supplier of high-quality air filtration products that are designed to meet the expectations of our customers. Through the use of latest technologies, we can improve the quality of our products and meet the expectations of our customers.

To comply with the requirements of ISO 9001, Compo has a dedicated quality management system that is designed to meet the requirements of this standard.

Reaching company targets with good teamwork, based on Total Quality philosophy.

To improve the efficiency of our operations, Our QC team can identify preventive measures that can be carried out through the self-assessment process.

To achieve continuous improvement, we can increase the efficiency of our processes. This process can help us meet the requirements of our customers and improve the quality of our products.

To improve our competence, we encourage innovation and technical training.

Compo has a comprehensive quality management system that is designed to help manage all of its activities. This system is integrated with other safety and environmental management systems.

Managing a solid supply chain plays a crucial role in efficient manufacturing. Compo practices responsible material sourcing by partnering with carefully picked suppliers through a strict selection process. Material suppliers are chosen based on several factors, including material quality, specification adherence,quality stability, response and delivery times, and pricing. By properly monitoring our supply chain, materials are guaranteed high-grade and at the best prices.

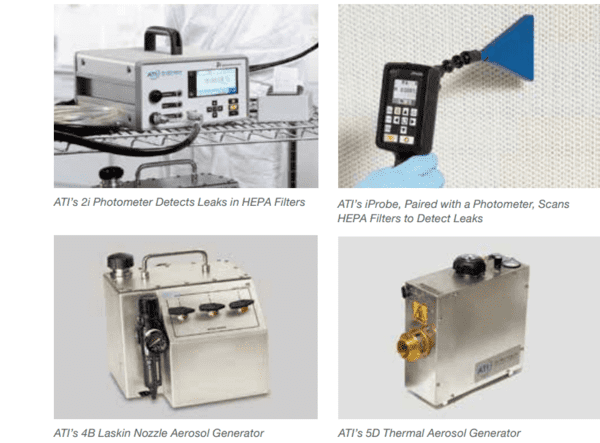

We understand that quality products begin with using top-notch materials. All incoming air filter materials are subjected to various testing with internal filter test equipment, making sure they pass global standards. Each air filter material should be test ok in terms of efficiency, air pressure drop, thickness, weight, tensile strength etc.

After production, each air filter goes through a series of tests to guarantee optimal performance. Efficiency and initial pressure drop should be tested before shipping.

To guarantee the utmost quality of our air filter products, our professional quality control team manages a comprehensive inspection process. From raw material inspection to final product inspection, our expert auditors review each part with high precision, raising the bar of quality production. We can also provide third-party quality inspections whenever needed, giving you more confidence in your products.

The stringent quality control standards we apply to our production process are based on globally-recognized institutions.

We satisfy all your air filtration requirements and would love to be your partner.

Be the first to know about regular product updates and promotion offers.

Copyright © 2022, Compo. All rights reserved. Powered by Compo

WhatsApp us